In September 2020, China announced its goal of peaking carbon emissions by 2030 and achieving carbon neutrality by 2060. The country’s hydrogen energy industry has entered into an upswing phase, aligning with efforts to meet these dual-carbon targets. Currently leading globally in hydrogen gas production with 37.81 million tons in 2022, China is poised for further growth in this sector. According to the China Hydrogen Energy Alliance, the industry’s value could reach RMB 5 trillion (USD 697.1 billion) between 2026–2035, painting a promising future for the hydrogen sector.

However, riding alongside this progress is a growing concern around water usage tied to hydrogen production. As the sector continues to expand, striking a balance between its development and impact on water resources will be essential.

On December 10, during COP28, the Water for Hydrogen Production report jointly written by the International Renewable Energy Agency (IRENA) and Bluerisk was officially released, providing a comprehensive analysis of the water-related issues associated with hydrogen production, offering a reference point for the sector.

Based on the report’s findings, hydrogen production is currently not considered a water-intensive industry despite exerting significant pressure on water resources in certain regions. For example, a coal gasification-based hydrogen plant (equipped with carbon capture, usage, and storage capabilities, or CCUS) can consume around half of the water utilized by the city of London for an entire year to produce 237 kilotons of hydrogen.

Prevailing hydrogen production methods are color-coded to represent the hydrogen produced via different pathways.

- Green hydrogen is produced using renewable energy-powered water electrolysis.

- Gray hydrogen is produced from methane through steam methane reforming (SMR), a method of extracting hydrogen from methane through a reaction with steam.

- Brown hydrogen is produced using coal gasification.

- Blue hydrogen is produced by integrating CCUS capabilities into the brown and gray hydrogen pathways.

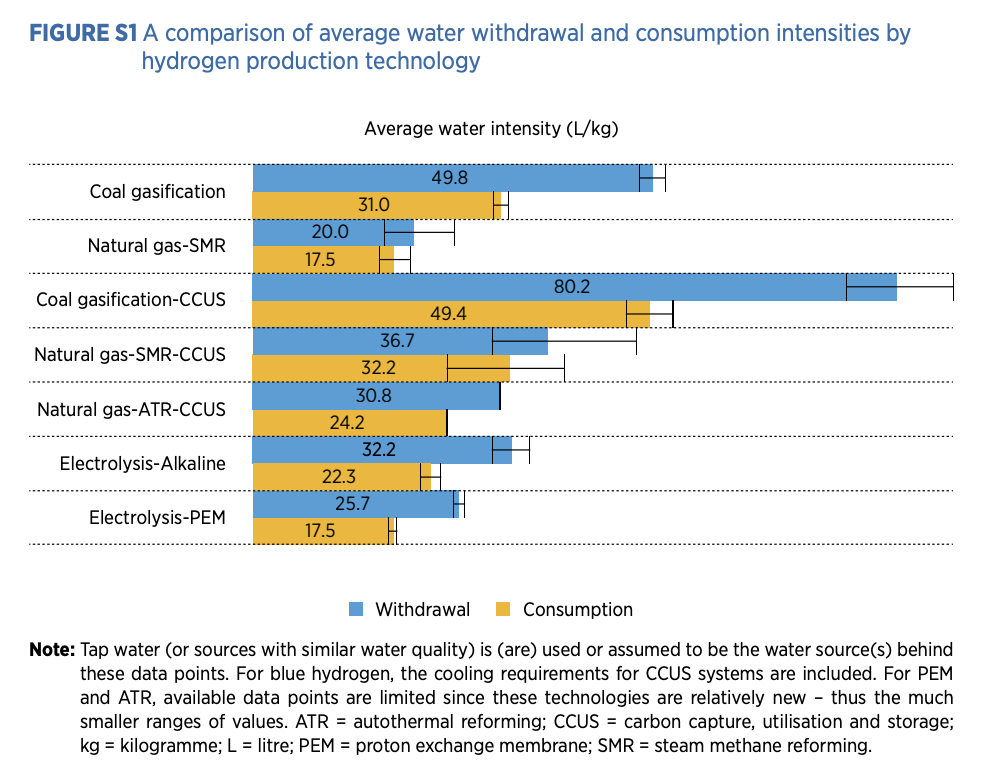

Green hydrogen boasts the lowest water intensity, requiring 17.5 liters of water on average to produce one kilogram of hydrogen, followed by gray hydrogen, blue hydrogen, and brown hydrogen.

When it comes to water efficiency, green hydrogen is seemingly the frontrunner. The report cited simulation results suggesting that as green hydrogen technology continues to advance, a 1% increase in electrolysis efficiency could lead to about a 2% reduction in water consumption.

On a global scale, the amount of water presently consumed to produce hydrogen isn’t substantial, representing an insignificant portion of total water consumption for both China and the energy sector as a whole. 2.2 billion cubic meters of global freshwater is extracted annually for hydrogen production, constituting only 0.6% of the energy sector’s total.

However, regions with higher hydrogen production capacities are noted to be subject to higher water stress levels. The report found that 35% of global green and blue hydrogen production facilities are situated in areas with high water stress, adding to the water-related issues that China, the European Union, the US, and other G20 nations are grappling with.

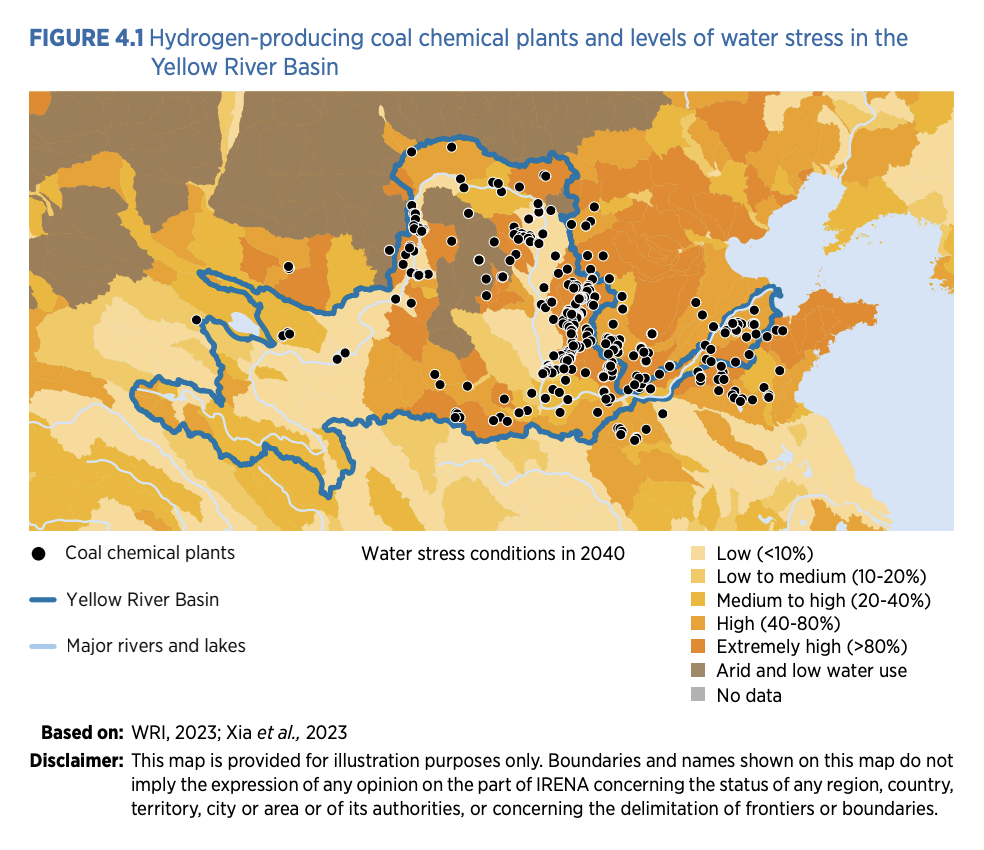

For example, China’s Yellow River basin hosts over 80% of the country’s coal chemical plants, accounting for more than 80% of the country’s coal-based hydrogen production capacity. However, the region’s water resources make up less than 4% of the national total, suggesting that a gap exists between water supply and demand. Consequently, the continuation of water-intensive coal-based hydrogen production in the area will perpetually increase local water burden, and should CCUS capabilities be introduced to reduce carbon emissions, water demand will likely surge significantly.

In light of this, the report suggests that, in the ongoing development of hydrogen energy in the Yellow River basin, choosing low water-consuming green hydrogen would be the optimal decision. According to the report’s calculations, transitioning from brown hydrogen to green hydrogen in the Yellow River basin, through methods such as SMR and CCUS, alkaline electrolysis, or a combination of both, could result in a 28% decrease in water extraction, a 20% reduction in water consumption, and an 11% increase in hydrogen production.

KrASIA Connection features translated and adapted content that was originally published by 36Kr. This article was written by Wang Fangyu for 36Kr.