Casbot, a Chinese developer of humanoid robots, has raised nearly RMB 100 million (USD 14 million) in an angel plus funding round. The backers include Lens Technology, Tianjin Jiayi, and existing investors SDIC Unity Capital and Henan Asset Management. The capital will be used for mass production, R&D enhancements, and market expansion.

Founded in August 2023, Casbot is based in Zhongguancun and focuses on the commercialization of general-purpose humanoid robots and embodied intelligence. Its core team comprises engineers with longstanding experience in precision assembly, flexible manipulation, and visual servoing—skills developed through national projects like the C919 aircraft’s high-torque nut assembly system, quadruped robots, and micro-target assembly platforms.

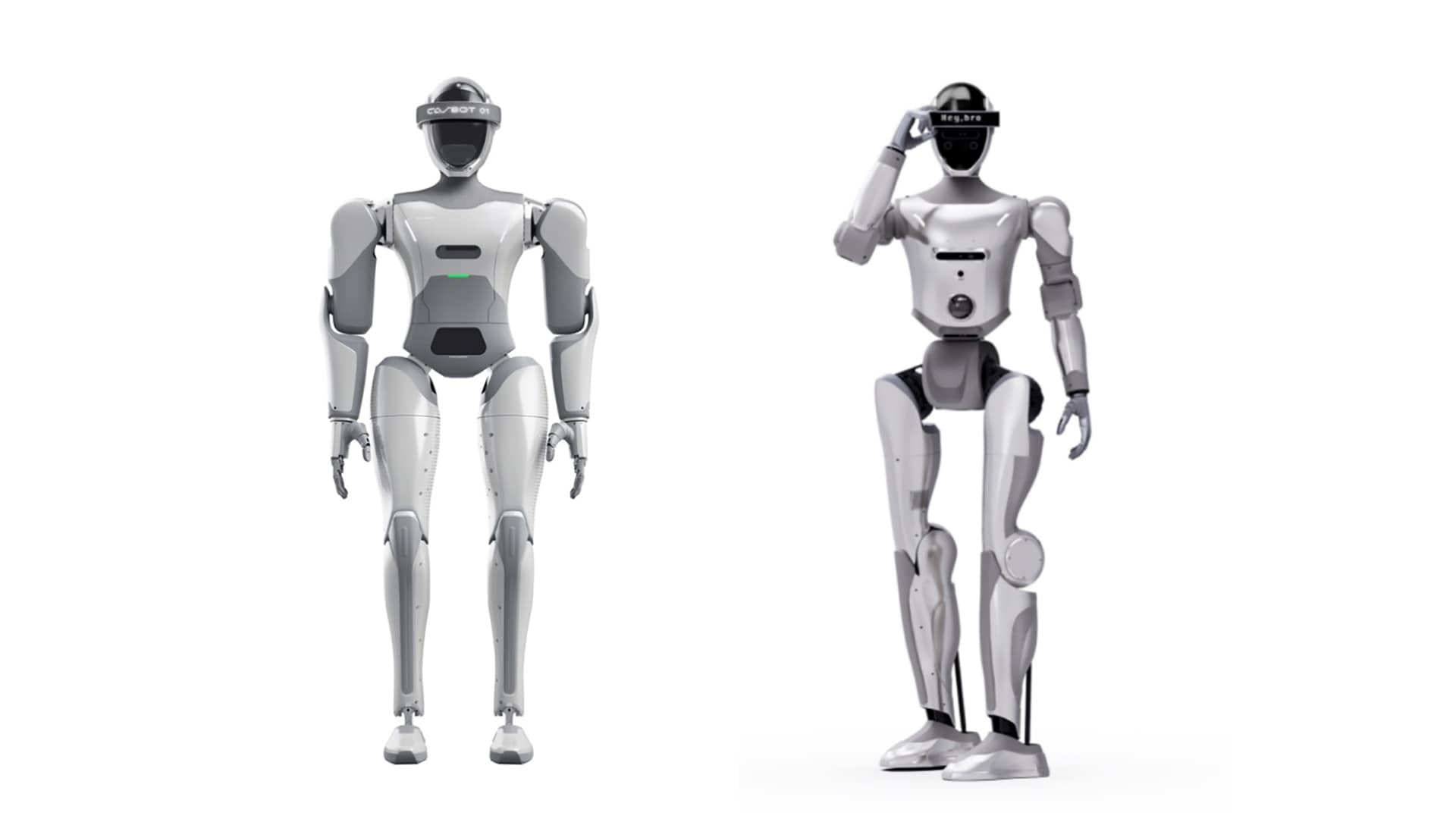

The company has introduced two bipedal humanoid robots: the Casbot 01, designed for versatile use cases with general-purpose intelligence, and the Casbot 02, a second-generation full-sized model. While the two share foundational technologies, they are intended for distinct applications.

The Casbot 01 stands at 179 centimeters and weighs about 60 kilograms. It offers 52 degrees of freedom, onboard computing power of 550 TOPS (tera operations per second), and can operate for more than four hours on a single charge. Designed for outdoor environments and specialized tasks, this model has been structurally and functionally optimized for roles in emergency response and industrial settings.

By comparison, the Casbot 02, launched in June, is a lighter dual-legged model, measuring 163 cm tall and weighing 55 kg. It is powered by a 275 TOPS chip and equipped with RGB-D cameras, inertial measurement unit (IMU) sensors, and a microphone array. These features enable visual and auditory perception, including facial tracking and voiceprint recognition. The robot is designed to maintain reliable communication even in noisy environments, supporting interactive use in consumer and institutional spaces.

Target venues for the Casbot 02 include science museums, exhibition halls, shopping centers, and automotive showrooms. It is positioned as a guide, greeter, or interactive presenter, with modular features built for future adaptability across varied application scenarios.

Technically, Casbot employs a layered end-to-end model architecture that incorporates reinforcement learning. This approach supports both logical task decomposition and dynamic training, enabling real-time adaptation to unpredictable variables such as environmental noise or human interference during physical tasks.

The system collects operational data in real-world settings, including force feedback and visual signal deviations, and uses closed-loop training to refine its movement control strategies. This enables the robot to adjust the precision and trajectory of its actions in tasks such as screw fastening or object sorting.

“This combination of layered architecture with reinforcement learning offers the best of both worlds,” said Zhang Miao, co-founder and COO of Casbot, in an interview with 36Kr. “It allows for logical task planning while empowering the system to evolve through real-world feedback, creating a full-loop intelligence pipeline from perception to execution. This makes it ideal for industrial quality inspections or underground operations, where robustness is critical.”

Casbot is currently prioritizing the industrial and mining sectors. Zhang noted that these areas have concentrated, well-defined use cases, making them more suitable for embodied robotics than less structured domains like education or general commercial services.

The company has already developed expertise and customer relationships in emergency response, underground mining, and industrial manufacturing. By concentrating on these demand-driven sectors, Casbot aims to scale production and lower unit costs. It also sees industrial deployments as a way to gather semi-structured operational data, feeding continuous improvements in its embodied intelligence models. This process supports an iterative cycle of deployment, feedback, and technical refinement.

Many factories face labor shortages and increasing demand for flexible manufacturing. Industries such as consumer electronics and apparel often rely on small-batch, high-mix production lines that traditional robots cannot manage effectively. For instance, quality inspection tasks may require coordinated two-handed actions—gripping, flipping, and placing items with precision—which standard single-arm robots are less suited for.

Casbot’s humanoid robots are equipped with dexterous five-finger hands that replicate human-level coordination. They can execute complex sequences such as screw fastening and cable insertion, and are capable of quickly learning and generalizing new tasks across settings, making them well-suited for dynamic production line reconfiguration.

According to 36Kr, Casbot has formed partnerships with major industrial players such as Zhaojin Group, Sinomine Resource Group, and CITIC Heavy Industries. These collaborations involve co-developing humanoid robots tailored for underground mining, safety patrols, and other specialized applications.

Beyond industry and mining, Casbot is also developing a standardized product line for education and commercial services. These systems use modular architecture for quick deployment and environmental adaptation.

Looking ahead, Casbot plans to broaden the deployment of humanoid robots across multiple sectors, advancing the application of embodied intelligence in real-world scenarios.

Lens Technology praised Casbot for balancing innovation with practical deployment, citing the relevance of its technology to factory operations. The company plans to support Casbot with component supply and assembly resources to help scale production while maintaining cost and quality control. It also intends to integrate Casbot into its smart manufacturing operations.

Tianjin Jiayi expressed similar views, emphasizing Casbot’s technical capabilities in mining and its ability to turn engineering expertise into sustainable business growth. “In a crowded field, we choose to back teams that truly understand both technology and the business fundamentals behind it,” the company said.

KrASIA Connection features translated and adapted content that was originally published by 36Kr. This article was written by Huang Nan for 36Kr.